Plasticizer?

What are plasticizers?

Plasticizers are additives that increase the flexibility or workability of the material that they are added to.

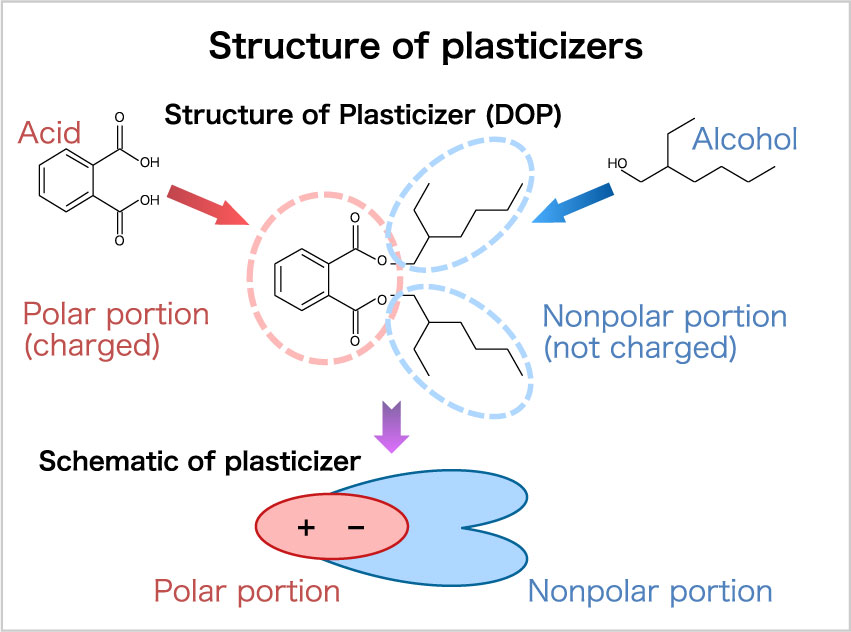

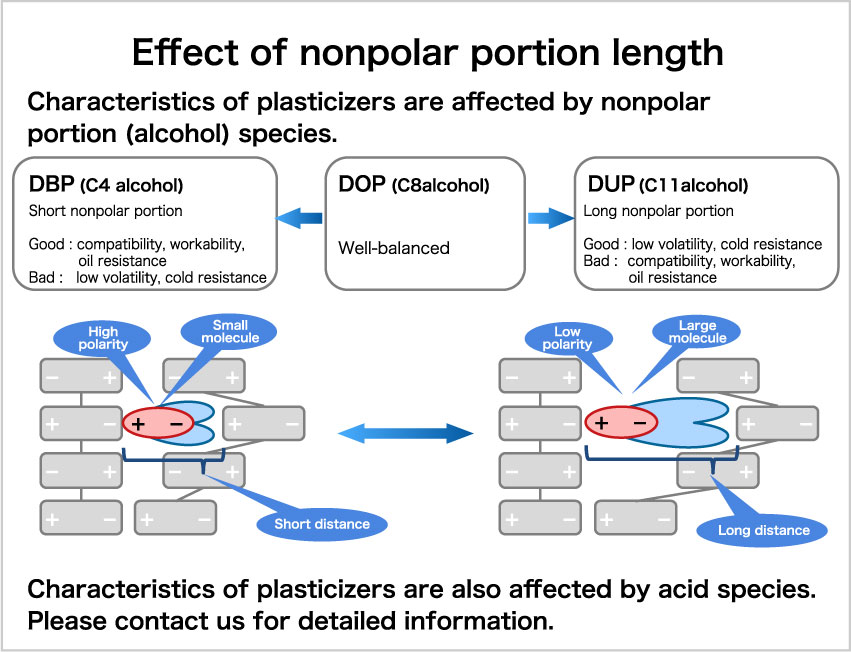

Almost all plasticizers are compounds, generally referred to as ester, which are synthesized from acids and alcohol and mainly used to soften plastics such as vinyl chloride (VC). The acids include phthalic acid, trimellitic acid and adipic acid. The alcohol used includes octanol, nonanol and mixed higher alcohol. Combining these acids and alcohols has created a variety of plasticizers. We provide the most appropriate plasticizers for their uses in the aspect of performance and cost.

Softening hard vinyl chloride

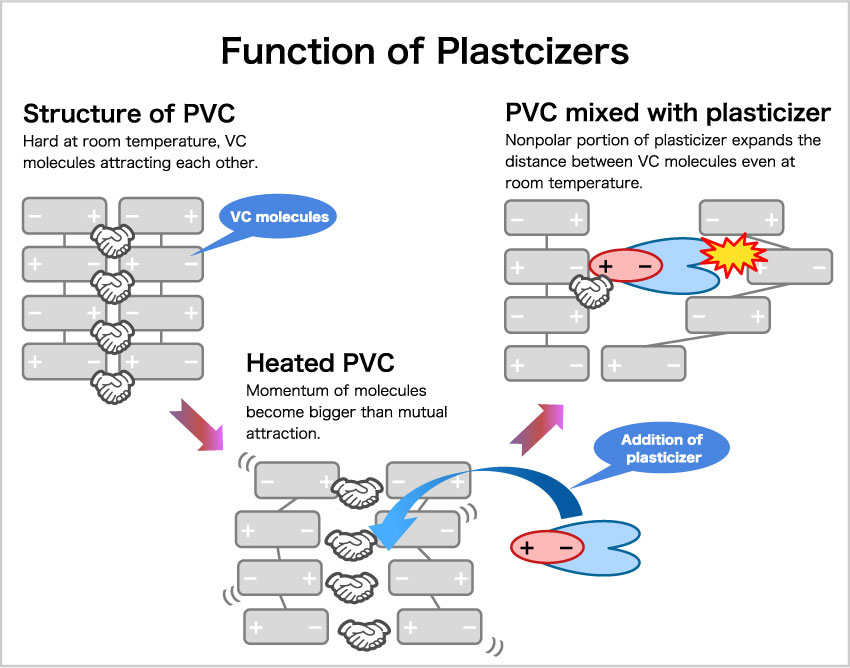

VC is a hard resin at room temperature because VC molecules attract each other to maintain their shape. Heating VC makes the momentum of the molecules greater than their mutual attraction, resulting in increasing the intermolecular distance and thus softening the VC. If plasticizer molecules are then introduced, the VC molecules are hindered from coming closer. Even if the temperature returns to normal, they remain soft. This is how plasticizers keep VC soft; the technical term is plasticization.

VC molecules are electrically biased with positive or negative polarity. Plasticizer molecules consist of a polar portion, which is positively or negatively charged, and a nonpolar portion, which is not charged. VC and plasticizers electrically bond at this polar portion and yet remain soft because the nonpolar potion expands the distance between VC molecules.

Performance required

for plasticizers

The basic properties required for plasticizers include a large molecular weight and high boiling point. If the former is too small or the latter is too low, then the plasticizer will evaporate during the hot VC formation process. The plasticizers are required to have both polar and nonpolar portions, as explained above. The result is that ester is appropriate for plasticizers. Among many esters, those providing the following performance are selected and used as plasticizer:

(1) compatibility and workability

(2) plasticization efficiency

(3) durability (low volatility, low transitivity and oil resistance)

(4) cold-, heat-, weather- and contamination resistance

(5) electrical insulation

Applications of plasticizers

Flexible PVC, made by mixing PVC with plasticizer, is used in various fields.

・Insulation and sheath of electrical cables

・Interior material such as wall papers, decorative films

・Flooring such as vinyl floors, carpet tiles, vinyl tiles

・Under body coatings, seal agents, surface layer of instrument panels of cars

・Building materials such as tarpaulins, waterproof sheets

・Agricultural materials such as agricultural films, hoses

・Food wrap films

・Infusion bags

As described above, plasticizers are closely related with our daily lives.

Contact Us

Tel.+81-3-3516-0345